What is Generative Design?

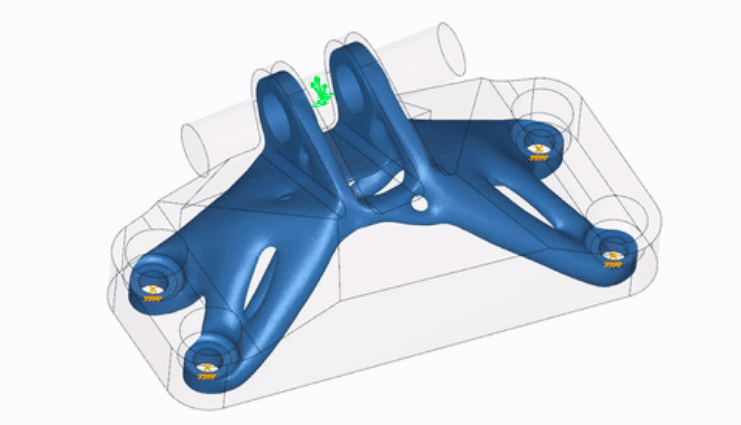

Generative design is a technology in which 3D models are created and optimized by computer software. A user sets up requirements for the model, such as manufacturing processes, loads, and constraints, and then the software offers designs that meet those requirements.

Compared to conventional design, generative design automates the whole CAD Design process to create more optimized designs. It is one of the driving factors in the Fourth Industrial Revolution.

Due to technology limitations, generative design software has applications in 3D printing or low production volume parts. But this software is evolving with time. In the future, they may become capable enough to design pieces for mass production as well.

Generative Design Software

Here generative design software is available in the market.

- Autodesk Fusion 360

- Solidworks Topology Optimization

- PTC Creo Parametric 7.0.2.0 GDX

- PTC Onshape and ParaMatters

- Catia Function Driven GD

- By-GEN ( From Blender)

- Solid Edge GD and Topology Improvement.

The Benefit of Generative Design

The overall benefit of generative design brings innovative products to market in record time. Though not as instantly apparent, there also makes a significant difference to companies that want:

Product differentiation. Most designs are based on models that worked before. We make incremental changes and hope it’s attractive to customers. The generative design allows you to set in on that rut by creating high-performing new parts and products that exceed requirements.

Optimized product costs. Generative design can save money by exterminating over-designed parts. These are designs that, while reliable, may use more materials or complex manufacturing methods than necessary.

Optimized reliability. Carry out stress analyses on the generative design results to validate the quality and durability of the designs. This ensures your design works in the real world. (it also saves costs in manufacturing and service support.)

Provide various design options. Generative Design software provides users different design options for a given product. As a result, engineers have various design options to choose from that are fulfilling product design requirements.

Reduced product weight. Simulation during the part design process helps in optimizing part weight while fulfilling other product design requirements.

Credit source:https://www.ptc.com

Generative Design Applications

Engineers are already starting to leverage generative design software to explore new design options. Following are some of the application examples where new product design is done using generative design.

Aerospace Industry

Jacob Engineering uses PTC Creo Generative Design to improve NASA’s life support backpack; Jacobs needed a design engine to challenge conventional design biases and deliver an optimal balance of performance and safety. The result Jacobs realized a part mass reduction of up to 50%, resulting in significant fuel savings and improved astronaut mobility.

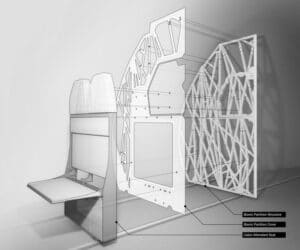

Aviation Industry

In a collaboration between Airbus and Autodesk fusion 360, used generative design to create an airplane cabin compartment. In this, they designed a bionic pattern to separate the passenger cabin from the galley. The result is reducing overall part weight (approx. 45%)

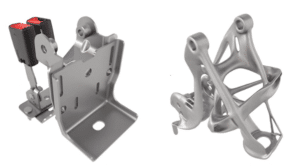

Automotive Industry

General Motor collaboration with Autodesk using the generative design technology in Fusion 360, GM engineers designed a new, functionally optimized seat bracket. This standard auto part secures seat-belt fasteners to seats and seats to floors. The new design results in the seat being 40 % lighter and 20 % stronger than its previous seat bracket.

Credit:www.autodesk.com

Furniture Industry

French designer Patrick Jouin revealed a prototype of the TAMU chair during Milan design week. The prototype features a design that is foldable and uses less material as possible.

Generative Design and 3D printing

Generative design is part of the family of Design for Additive Manufacturing (DfAM) techniques. Given that additive manufacturing enables a new level of design freedom, it makes sense to use it for complex models that require a more flexible manufacturing method. However, additive manufacturing is not always the technology you want to use with generative engineering.

We explain in more detail: Many parts are manufactured with 3D printing to be done more effectively using traditional manufacturing methods. Alternatively, traditionally manufactured parts could be done more effectively with the right design, increasing part performance and reducing waste by using additive manufacturing. It is not about pushing all designs to be additive but rather making sure that the right design is going into the right manufacturing technology to achieve the most desirable outcome.

Nevertheless, the design freedom enabled by additive manufacturing technologies can be very beneficial to leverage the opportunities of generative design. For example, it is possible to find structural, thermal, and flow solutions and engineering-based part orientation optimization to minimize surface area, support volume, overheating or printing time.

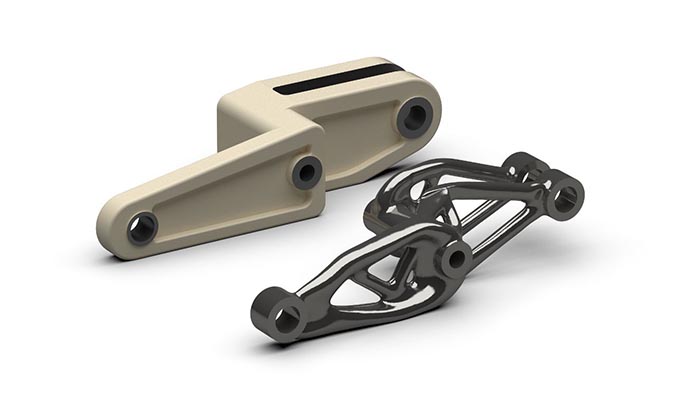

How is Generative Design Different Than Topology Optimization?

It’s helpful to understand the difference between generative design and topology optimization because the two terms are often used interchangeably. From our interview, Topology optimization converges on a single solution based only on functional objectives, constraints, and loads. Generative design evolves multiple solutions simultaneously to connect the best possible solutions based on practical and non-engineering requirements.

To summarized, Generative Design is changing the way engineers design products. It helps in creating low-cost, low-weight, highly optimized products. For more detailed information or to learn more, visit Convergence Consulting website.

Leave a Reply