Model-Based Design

Today’s business environment is complex, dynamic, and intricately interdependent and hence challenges the limits of traditional approaches. To answer this complexity, a Model-Based Design approach is emerging.

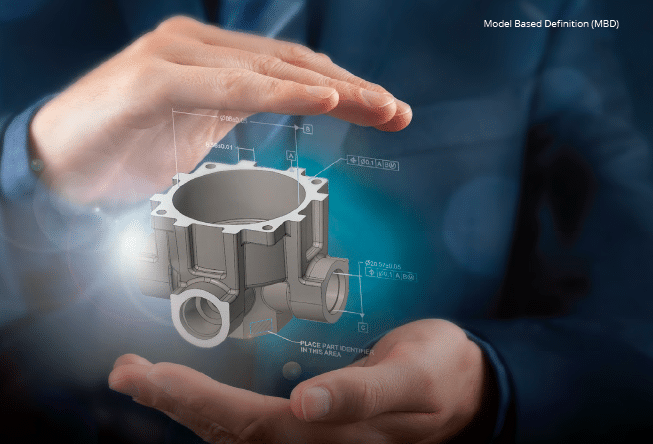

Since the 1990s, model-based definition (MBD), a technique for semantically documenting the information necessary to manufacture, inspect parts and assemblies produced via 3D computer-aided design (CAD), still isn’t in widespread use, says Dave Martin, former senior learning consultant at software company PTC. Currently, many engineering companies are still passing deliverables to manufacturers in 2D drawings accompanied by written product manufacturing information (PMI) about dimensions, geometric tolerances, and other essential parameters. Manufacturers are then required to transcribe this information into their software manually.

By contrast, MBD can provide a standardized technical data package containing the CAD model in its native format, a bill of materials in Microsoft Excel or CSV form, and other related electronic data such as notes, schematics, and first article inspection documents. In addition, MBD deliverables include annotation planes to define the placement and orientation of details to be placed in the model, 3D annotations containing PMI, and combination states to organize the 3D annotations for the sake of clarity.

Model-Based Design (MBD), essentially, is about creating rich “Technical Data Packages (TDP),” which includes 3D models and associated data elements that fully define the product in a manner that can be communicated and used successfully by all downstream customers without the need for 2D drawings. This TDP becomes the single source of truth exchanged with the downstream organizations such as quality, inspection, manufacturing, procurement, and others to interrogate, analyze, build and inspect the product.

Credit sorce:https://www.ptc.com/en/technologies/cad/model-based-definition

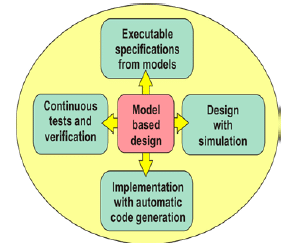

Model-Based Design (as shown in the picture below) allows you to improve efficiency by :

-

- Using a familiar design environment across project teams.

- Linking designs directly to requirements.

- Integrating testing with design to in perpetuity identify and correct errors.

- Refining algorithms through multi-domain simulation.

- Automatically generating embedded software code.

- Developing and reusing test suites.

- Automatically generating documentation.

- Reusing designs to install systems across multiple processors and hardware targets.

With Model-Based Design, engineers use models as a golden reference that links every part of the development process requirements, design, implementation, and testing. The time invested in creating models in advance saves more time at every subsequent stage of the development process through reuse or intricacy of design elements or by identifying errors when it is less time and cost-consuming to fix them.

Credit source: https://www.researchgate.net/publication/259443931_Model_Based_Design_and_HIL_Simulations

Example of the Benefits of Model-Based Design in the Automotive Sector

(but the benefits remain equally valid in sectors such as aeronautics, that of packaging automation, and wherever it has to work with large assemblies.)

- Increase in productivity: All the stages are based on the same mathematical model; thus, there is no need to develop sketches, mock-ups, and prototypes, and various models may be used for simulation without increasing the development time or cost.

- Decreased development time and cost: Model-based design is associated with rapid prototyping and validation of models and coding automation, which considerably speeds up the overall development process. Since testing is performed at each stage, the development team can avoid costly and risky product changes later.

- Ability to introduce significant changes significant to the development process: Block-oriented workflow and automatic code generation allow automotive engineers to correct wrong specifications and replace large functional blocks even if the product is late into the development cycle.

- Consistent documentation and implementation: A model description becomes the basis for system documentation, considerably reducing the documentation cost and the related errors. Since the model description is also the basis for real code, documentation and implementation are kept consistent.

- A more reliable automotive systems functionality system as a whole is a crucial focus from the very beginning of individual component development. In addition, large simulations, early testing, and automatic code generation eliminate the possibility of code errors and reduces the need for in-system debugging.

- Simple reuse of the solutions: The generated models can be reused in various applications and under different operating conditions. Simulation blocks and vehicle tests can be saved in a library and reused in the process of development of other models too.

Credit source:https://medium.com/the-research-nest/

We believe that it could be helpful to introduce and clarify some other concepts that look similar but are different: MBSE: Model-Based System Engineering and MBE: Model-Based Enterprise (MBE)

- Model-Based System Engineering (MBSE) is a system engineering initiative to create a digital model of a system that is used by all engineering control and other functional organizations within a company.

- Model-Based Enterprise (MBE) is a company-wide initiative to augment 3D models with additional information to create new documentation deliverables beyond engineering.

Model-Based Systems Engineering (MBSE)

Model-Based Systems Engineering (MBSE) is a systems engineering methodology that focuses on creating and exploiting domain models as the primary means of information exchange between engineers, rather than on document-based information exchange.

MBSE is generally defined as a formalized application of modeling to support system requirements, design, analysis, verification, and validation activities beginning in the conceptual design phase and continuing throughout development and later life cycle phases

Credit source: https://www.plm.automation.siemens.com/global/en/our-story/glossary/what-is-model-based-systems-engineering/28573

Model-Based Enterprise (MBE)

Model-based enterprise (MBE) is an engineering strategy that aims to clarify design intent during the manufacturing process by using a 3D model-based definition (MBD) that includes all the product and manufacturing information (PMI) associated with manufacturing the product. The goal of MBE is to improve efficiency, produce better quality products and reduce costs.

What are the Differences?

So, as you can see, these three significant sets of initiatives are each relevant to a different engineering domain: mechanical, system, and embedded systems. But the more fundamental difference runs much deeper than that. One focuses on documentation that is released by engineering (MBD and MBE). Another provides a single unambiguous definition of the design for engineering coordination (MBSE).

MBD Conclusion

The model-based design contributes to faster releases, enhanced innovation, and better reliability of automotive embedded systems. It demonstrates outstanding benefits and becomes more commonplace in the automotive industry. The tools for software modeling and simulation progress too continuously improving the representation of automotive systems. Such interconnection is sure to make a model-based design even more potent, ousting traditional methodology from the automotive landscape.

Convergence Consulting believes that the advent of 3D model-based design (MBD) integrated with manufacturing technology can offer substantial productivity advantages over the use of traditional 2D engineering drawings to drive manufacturing.

Discover how Convergence Consulting can help your business to implement the model-based design.

Leave a Reply