Credit picture:https://www.roboticsbusinessreview.com/

Industrial manufacturing is nearing a milestone, wherein the workforce, having amassed years of valuable experience and knowledge, is preparing to retire. This is critical for several reasons. Traditionally, these experts act as mentors to novices and apprentices, demonstrating the proper workflow methods and identifying shortcuts and tips. So they will take their years of valuable expertise with them.

Accordingly, this situation represents a challenge and, at the same time, an opportunity. We have to capture that knowledge and leverage it for training new or redeployed workers.

Technology’s Role in Knowledge Transfer and Training.

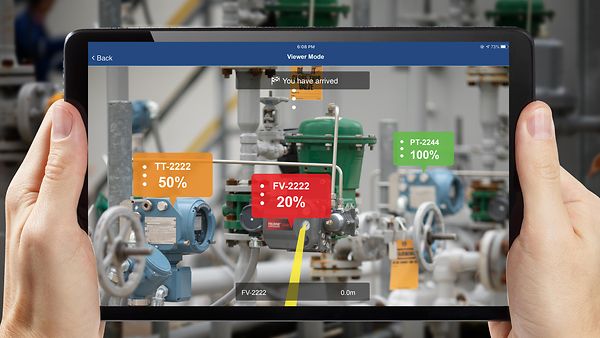

Augmented Reality covers digital content in your field of view of the physical world. This can include charts, data, tables, diagrams, images, and video, in addition to 3D content. The solution here is that the wearer of an AR head-mounted display (HMD) or a tablet or mobile device user has clear sight of the physical world around them while they are doing their work. This differs from AR’s cousin, virtual reality (VR), in which the physical world is entirely obscured by digital content. Furthermore, AR can be classified into primary and advanced AR. Basic AR refers to those AR experiences in which content is shown in the user’s field of view but cannot work (e.g., stretched, rotated, spun, or moved around).

Conversely, advanced AR allows the wearer to operate content within the field of view. By way of example for advanced AR, a virtual motor engine is affected apart with different pieces moved around, stretched out, rotated around, or placed in another area within the field of view. This contrasts with fundamental AR, in which the same virtual motor engine can come up within the field of view, but the user cannot manipulate it in the same way. This is a critical difference between knowledge transfer and training, yet both are important.

With advanced AR, users get a 3D view of the content that presenter itself to the real-world environment, providing nearly seamless viewing between the physical and the digital. This becomes especially helpful when a worker has multiple steps and multiple locations to work on a machine. With fundamental AR, users get a 2D view of the content, similar to having a tablet close to one’s eyes. This results in a look-up/look-down user experience, suitable for those situations where the user can consume short pieces of information on the display while completing a task.

Credit picture:https://www.ptc.com/

Augmented Reality has been gaining ground as a teaching and training tool within industrial manufacturing. It started as see-what-I-see and expert-in-your-ear shared experiences, also visualizing hidden components inside products. It’s a vital step forward compared with the traditional way of spending endless hours of classroom training with PowerPoint slides and training manuals.

As a result of incorporating Augmented Reality into a company’s training program, managers of frontline workers can:

- Speed up the training process

- Update digital content and adjust training programs as required

- Offer more effective training and new skills development to employees

- Lower training costs

- Teach safety requirements and increase compliance to standard operating procedures.

The consequences of an AR-based training program begin to emerge. Organizations can reduce or eliminate costly mistakes; improve first-time fix rates, quality, and throughput; and move novice workers into more complex tasks with greater efficiency. While still a relatively new technology, augmented reality continues to evolve and gain traction in the industrial market. For training and skills development, capturing the deep knowledge of experienced workers and subject matter experts and then transforming it into AR content that can empower new and redeployed workers has become faster and easier than previously thought possible.

This solves the challenge of saving and retain expertise before it leaves the company, keeps it always on-demand, and presents it in a way that novice workers can quickly learn and use that knowledge. The result is an on-demand AR experience featuring step-by-step expert instruction and digital content designed to help workers successfully operate, set up, and maintain machinery, complete product assembly, and perform maintenance and service tasks precisely and safely.

Credit picture:https://www.automationworld.com/

The Benefits of Augmented Reality

Companies realize several benefits by capturing expert insight, procedures, and know-how and transferring that knowledge into AR experiences quickly and easily scaled to frontline workers across the organization.

First, consider how this approach aligns well with how novice workers learn from seasoned veterans: They can learn how to safely operate a piece of equipment, how standard procedures should be performed, and how to avoid safety hazards and costly mistakes. This goes above and beyond book-based instruction, reducing the lengthy process requiring experts to spend time bringing new workers up to speed instead of working on high-value tasks.

Second, it gives managers the flexibility they need to instruct novices successfully. Content can be created with insight from multiple experts as they go about their work and be updated as the workflow evolves – especially as new machines come online and new workflow methods are developed. Learning can take place on the job without the need to take down equipment or shut down high-volume production lines.

Third, AR-based knowledge transfer flattened the learning curve and reduced the time needed for training, but it plays a vital role in helping trainees retain knowledge. Novices can more easily recall what they saw and heard than remembering what they read in a manual. This also helps with employee satisfaction and retention.

AR-based knowledge transfer and training benefit companies by giving trainees access to expertise that aligns with their learning style to perform and complete their work. It also offers managers and subject matter experts the flexibility to create effective training materials when and where they are needed most while reducing costs.

With Convergence Consulting’s expertise in this field, companies can reap the benefits of knowledge transfer through a project of Augmented Reality. Novice workers can reduce their training time and improve the quality of their work, including improved error reduction and first-time fix rates. In addition, they are taught proper safety and compliance procedures. Likewise, companies reduce associated training costs with less waste. But perhaps most importantly, trainees learn and retain knowledge better, having seen someone do the work before doing it themselves.

Leave a Reply