Shorter Development Time, Lower costs and Improve the Quality of the products is ever since one of the main goals of manufacturing companies. Nowadays, this objective is even essential for the survival of the company itself.

Shorter Development Time, Lower costs and Improve the Quality of the products is ever since one of the main goals of manufacturing companies. Nowadays, this objective is even essential for the survival of the company itself.

For this reason, we consider it useful to go back to talking about QFD. Because QFD reduces the likelihood of late design changes by focusing on product features and improvements based on customer requirements. Effective QFD methodology prevents valuable project time and resources from being wasted on the development of non-value added features or functions.

What is Quality Function Deployment (QFD)?

Quality Function Deployment (QFD) is a process and set of tools used to effectively define customer requirements and convert them into detailed engineering specifications and plans to produce the products that fulfill those requirements. QFD translates customer requirements (or VOC) into measurable design targets and drives them from the assembly level down through the sub-assembly, component, and production process levels. QFD methodology provides a defined set of matrices utilized to facilitate this progression.

QFD was first developed in Japan by Yoji Akao in the late 1960s while working for Mitsubishi’s shipyard. It was later adopted by other companies, including Toyota and its supply chain. In the early 1980s, QFD was introduced in the United States mainly by the big three automotive companies and a few electronics manufacturers. Acceptance and growth of QFD in the US were initially relatively slow but have since gained popularity and are currently used in manufacturing, health, care, and service organizations.

The House of Quality (HOQ)

The house of quality is part of the QFD system. As a primary essential design instrument of quality function deployment, it defines and classifies customers’ desires, identifies their importance, specifies engineering characteristics, and assigns priorities for the system requirements.

House of Quality refers to a well-known process for product development inspired by customer desires for product or process development and anchored by the capabilities and resources of the organization seeking to meet those desires. It is a process of listening to customers, translating their passions into a written plan, prioritizing execution steps based on the most important to the customer, and putting a realistic plan on paper.

“Product development inspired by customer desires.”

House of Quality Example | QFD Matrix

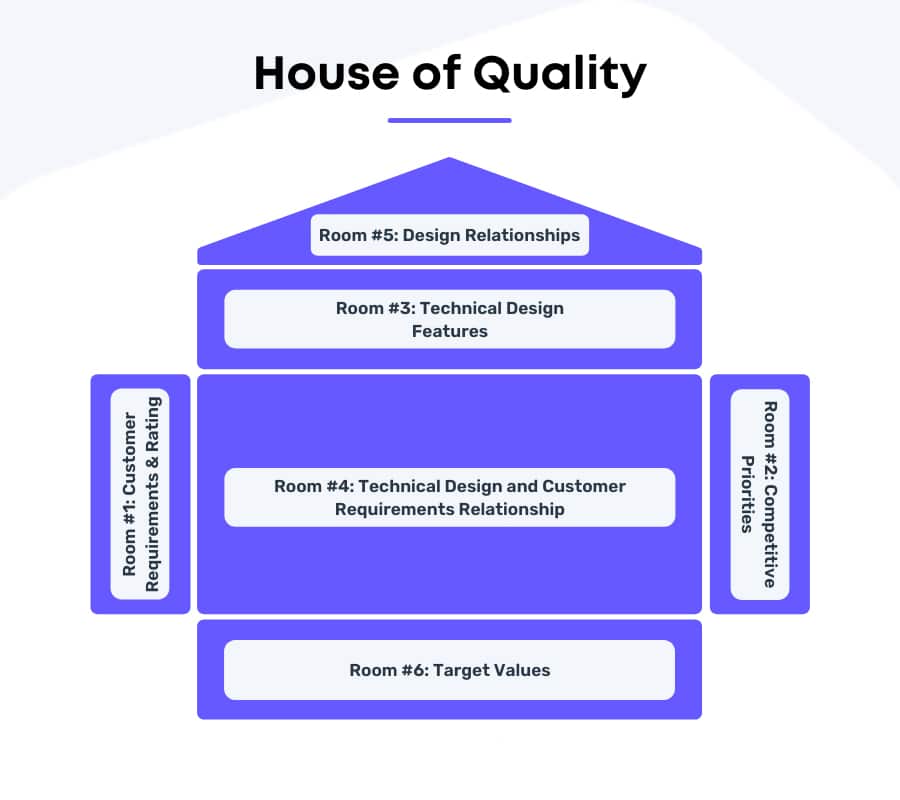

There are six main rooms or areas inside the House of Quality. Here is an overview of how to effectively use the House of Quality template:

- Customer Requirements and Rating – Location, on the left side of the house, this room lists the customer requirements gathered from the research and how they’re ranked based on their degree of importance.

- Competitive Priorities – Placed on the right side of the house, this part outlines the top points of comparison between the customer requirements and the needed innovations based on competitor analysis.

- Technical Design Features – Listing product’s design features duct; this section is placed just above the base, making it the attic house.

- Technical Design and Customer Requirements Relationships – Found at the base of the house below the attic, this part is responsible for visualizing and rating the impact of the design features on the priority list of customer requirements.

- Design Relationships – Also known as the roof matrix, this describes the interrelationship between the design features.

- Target Values – Lastly, the basement of the house lists the target values that serve as an organization’s way of quantifying objective measures to help evaluate each design feature or characteristic.

Importance of QFD and HOQ for Product Development

Quality Function Deployment (QFD) and House of Quality (HOQ) is a planning process for products and services that starts with the voice of the customer. It enables people to think together. People will be better aligned and able to think together towards solutions.

QFD, in the early stages of the design phase, helps to incorporate all the customer needs into the final product. Furthermore, it is a planning tool to determine critical vital areas in which the effort should be about to our technical capabilities.

The method to produce products according to consumer tastes and desires is QFD; it can help determine which products and services are according to what customers want through product and service attributes. QFD has a degree of importance, level of difficulty, and cost estimates that can be the focus of improvement.

Product Development steps- Four primary phases of QFD

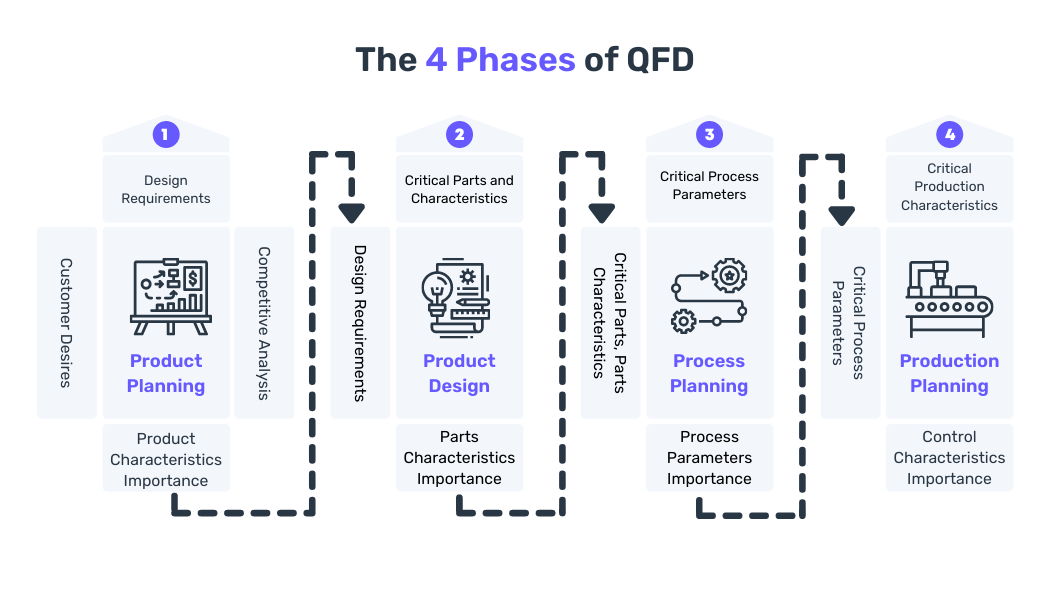

Product planning:

- Identify customer requirements

- Translating VOC into design specifications or product control characteristics in the form of a planning matrix.

- Prioritize requirements

- Evaluate competition and prioritize requirements

Product design:

- Generate design ideas or concepts

- Translate the outputs of the product planning phase into individual part details that define part characteristics.

- Identify product risks.

- Define the product specifications

Process planning:

- Defines the product development process and establishes critical component parameters.

- Establish critical process controls

- During process planning, create a manufacturing process flowchart, document, and process parameters (or target vaunted).

Process control (production planning):

- Define the production requirements for each component/operation.

- Establish inspection and test methods

- Define performance indicators to monitor the production process

Conclusion

QFD and HOQ will assist you in achieving the following goals:

- To define the essentials, you should put them in your product.

- To identify extraneous aspects that can be removed.

- To prioritize the desires and requirements of your clients.

- To get a vision bout your situation in the market.

- To clarify essential technical features of the product.

- To find out the objectives for the tech features that should be implemented in the future.

Convergence Consulting offers particularly qualified consultancy services within the product development process. Contact us!

Leave a Reply