Nowadays, every company is looking to increase their performance through new methodologies and/or technologies that can offer a quantum leap in generative design and development. Today we want to talk about a new quantum leap: “Performance-Driven Generative Design Methods.”

Performance-driven generative design methods can produce and stimulate solutions based on robust and rigorous design conditions and performance criteria. Using generative methods, the computer becomes a design generator in addition to its more conventional role as draftsperson, visualizer, data checker, and performance analyst.

Generative design is an iterative design process that involves a program that will generate a certain number of outputs that meet certain constraints, and a designer that will fine-tune the feasible region by changing minimal and maximal values of an interval in which a variable of the program meets the set of constraints, to reduce or augment the number of outputs to choose from.

Generative design software autonomously creates optimal designs from a set of system design requirements. Engineers can interactively specify their requirements and goals, including preferred materials and manufacturing processes and the generative engine will automatically produce a manufacture-ready design as a starting point or as a final solution. As a result, engineers can interact with technology to create superior designs and innovative products more quickly.

#What’s unique about generative design?

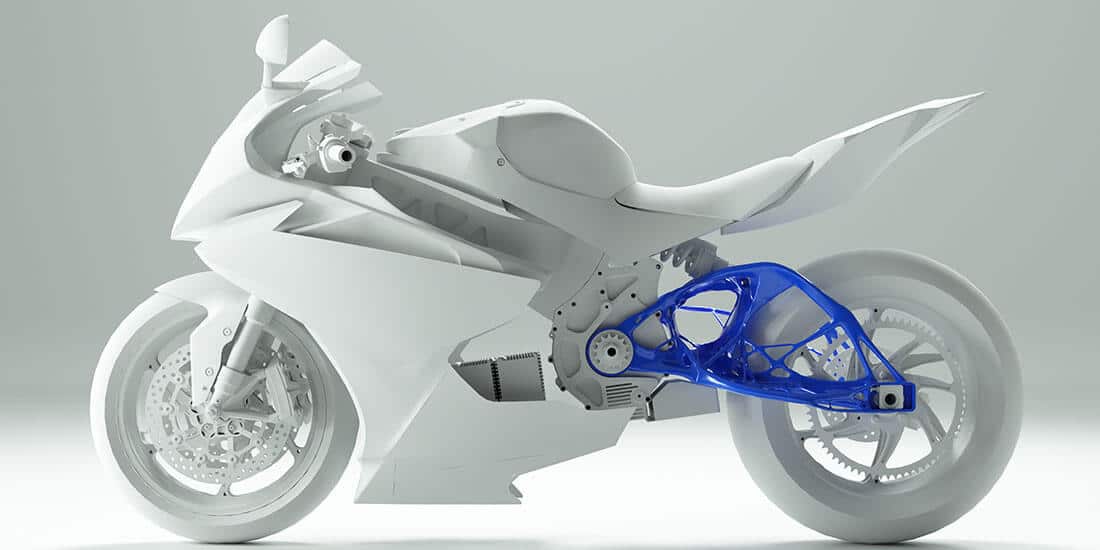

With a traditional design, you typically create multiple concepts, then evaluate and optimize one or more, based on your design goals. With generative design, you start with your design goals, and algorithms automatically generate optimized design options for achieving them. You can create multiple iterations of designs, identifying alternatives to meet various goals (i.e., weight, cost reduction). The process often results in organic forms similar to those seen in nature.

#Why Generative Design?

The typical design process often referred to as the traditional design process, requires the designer’s knowledge and expertise to craft products that meet the needs of the end-user. Usually, a laborious process requires designers and engineers to meticulously understand various principles and processes to generate a final design adequately. Even then, and after many hours of design, analysis, and prototyping, the pressures to reduce the development cycle often result in designs that are far from optimal.

Combine this with the next generation of emerging products, which require ultra-high performance characteristics and are too demanding for the traditional design process. This is where the generative design will help create the optimized designs of the future.

With the emergence of technologies such as artificial intelligence algorithms and infinite computing, which are much more accessible than any time in the past, designers and engineers can co-create designs using parameter-driven optimization.

#How it Works

Generative design software is not CAD software, but an adjunct to it. Generative design is available as part of Autodesk’s Fusion 360 CAD software, PTC’s Creo, and Siemen’s NX. However, engineers do not necessarily have to change CAD platforms to take advantage of generative design.

“We’re augmenting CAD,” says Jesse Blankenship, senior vice president of technology for PTC.

“We’re transforming it from the inside out: This is a real renaissance with CAD.”

source: https://www.assemblymag.com

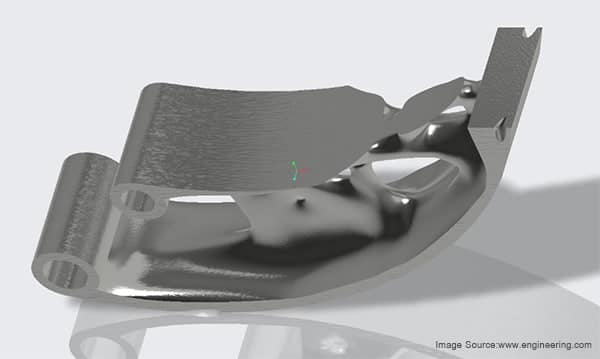

Generative design is more than just topology optimization. A function of some CAD software packages, topology optimization, is a mathematical method that optimizes material layout within a given design space for a given set of loads, boundary conditions, and constraints. Topology optimization is different from shape optimization and sizing optimization in that the design can attain any shape within the design space, instead of dealing with predefined configurations.

For example:

When designing a lever mechanism, engineers would need to know the three points in space where the lever will connect to other parts of the machine. These are the locations of features, such as holes to accept a bolt or axle, that won’t change no matter what form the final part takes. These points are known as the “preserved geometry” of the part.

From there, engineers input various constraints and requirements. “The part must weigh no more than X grams.” “Point A will see a moment load of Y newton-meters.” Engineers can input the cost requirements and safety factors. And they can ask the software to prioritize specific parameters, such as weight or strength.

Engineers can enter as much or as little information as they want. For example, if engineers already know the part must be made of, say, stainless steel, that information can be included in the constraints. If a material choice has not been chosen, engineers can let the software decide the best material based on the inputs. Similarly, engineers can input their preferred manufacturing methods or let the software choose how best to make the part.

#Creo Generative Topology Optimization

Our Creo Generative Topology Optimization extension creates optimized product designs based on your constraints and requirements—including materials and manufacturing processes. Rapidly explore innovative design options to reduce development time and expense, all within the Creo design environment. See how the Generative Topology Optimization extension automatically delivers high-quality, lower-cost, manufacturable designs.

What is the benefit of this enhancement?

You can automatically generate design based on critical goals, materials, physics, and manufacturing processes. With Generative Topology Optimization you can perform the following actions:

- Explore different design solutions based on critical goals, materials, physics, and manufacturing constraints.

- Define multiple design conditions for exploring alternative optimized solutions and then compare the results.

- See the results update automatically when you modify the design model or optimization input values.

- Integrate results to review stresses and deformation.

- Output the selected result as new fully-featured parts, to further refine the design.

- Easily modify the design and update the optimization.

- Analyze the model in Creo Simulation Live with original, optimized conditions.

Use Generative Topology Optimization to increase engineering productivity and improve innovation and conceptual design exploration. Develop higher-performance designs that are lighter weight with improved durability.

For more information, please see our portfolio:https://convercon.com/portfolio/