Introduction

Additive Manufacturing, colloquially known as 3D printing, has progressively gained importance not only in various fields of business but also in the daily life of consumers. The technology is capable of joining various materials and creating objects from 3D data, usually, layer upon layer in contrast to traditional subtractive manufacturing technologies. Additive manufacturing has been called a disruptive technology that will fundamentally influence many processes in production, supply chain design logistics, product life-cycle planning, and also consumer behavior.

Additive Manufacturing is not only a disruptive technology that has the potential to replace many conventional manufacturing processes but is also an enabling technology allowing new business models, new products, and new supply chains to flourish.”

The Evolution

The evolution of Additive Manufacturing (AM) over the past three decades has been nothing less than extraordinary. AM has experienced double-digit growth for 18 of the past 27 years, taking it from a promising set of uncommercialized technologies in the early 1980s to a market that was worth over $4 billion in 2014, is expected to grow to more than $12 billion by 2020 and it is anticipated to reach around USD 78 Billion by the year 2028. This growth has been made possible by improvements in AM and technologies. It is being driven by the market factors that necessitate its use, such as shorter product development cycles, increasing demand for customized and personalized products, increased focus and regulations on sustainability, reduced manufacturing cost and lead times, and the introduction of new business models.

During the past 30 years, the use of AM technology has also transformed. Early AM applications focused on models and prototypes. As the technology matured, AM played a major role in producing rapid and soft tooling (e.g., vacuum and silicone casting molds. Today it is also used for the production of end-use parts and products.

Additive Manufacturing covering all the following technologies & all applications:

- Rapid Prototyping (RP)

- 3D Printing (3DP)

- Rapid Tooling (RT)

- Rapid Manufacturing (RM)

- Additive Fabrication (AF)

- Additive Layer Manufacturing (ALM)

- Direct Digital Manufacturing (DDM)

Additive Manufacturing (AM) encompass:

#SLA

High-end technology utilizes laser technology to cure layer-upon-layer photopolymer resin (polymer that changes properties when exposed to light).

The build occurs in a pool of resin. A laser beam, directed into the resin pool, traces the model’s cross-section pattern for that particular layer and cures it. During the build cycle, the platform on which the build is repositioned, lowering by single-layer thickness. The process repeats until the body or model is completed, and fascinating to watch. Specialized material may be needed to add support to some model features. Models can be machined and used as patterns for injection molding, thermoforming, or other casting processes.

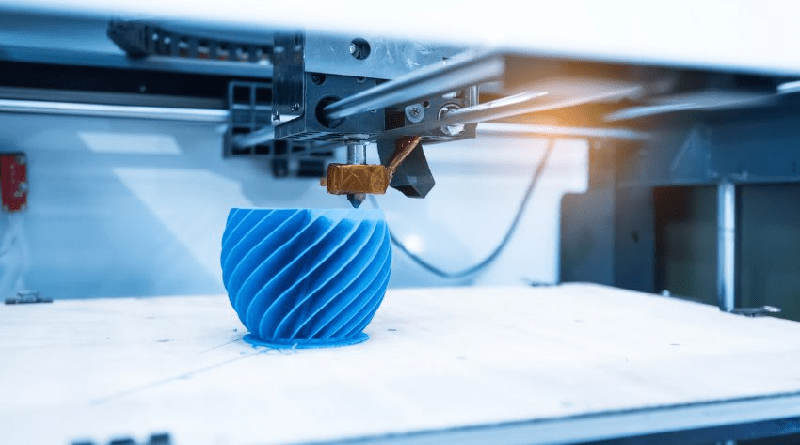

#FDM

Process-oriented involves using thermoplastic (polymer that changes to a liquid upon applying heat and solidifies to a solid when cooled) materials injected through indexing nozzles onto a platform. The nozzles trace each layer’s cross-section pattern with the thermoplastic material hardening before applying the next layer. The process repeats until the build or model is completed, and fascinating to watch. Specialized material may need to add support to some model features. Similar to SLA, the models can be machined or used as patterns. Very easy-to-use and cool.

#MJM

Multi-Jet Modeling is similar to an inkjet printer in that ahead, capable of shuttling back and forth (3 dimensions-x, y, z)) incorporates hundreds of small jets to apply a layer of thermopolymer material, layer-by-layer.

#3DP

The involves building a model in a container filled with powder of either starch or plaster based material. An inkjet printer head shuttles apply a small amount of binder to form a layer. Upon application of the binder, a new layer of powder is swept over the last layer to use more binders. The process repeats until the model is complete. As the model was supported by loose powder, there is no need for support. Additionally, this is the only process that builds in colors.

#SLS

Somewhat like SLA technology Selective Laser Sintering (SLS) utilizes a high-powered laser to fuse small particles of plastic, metal, ceramic, or glass. During the build cycle, the platform on which the build is repositioned, lowering by single-layer thickness. The process repeats until the shape or model is completed. Unlike SLA technology, the support material is not needed as the build is supported by unsintered material.

What is Additive Manufacturing?

Additive manufacturing (AM) is a term used to describe the set of manufacturing processes that progressively add layers of material to manufacture your products, and it could change the way you go about engineering your products. Instead of being held back by manufacturing constraints, you can design the component you need, focused only on the function it requires to perform and meet clients’ needs. You have full control over the interior structure of the part, so you can include voids, lattices, and other hard-to-manufacture structural components that can help cut down on material use and increase functionality. Subassemblies that used to require multiple parts can be combined into a single component. You can customize everything you make to suit your individual customers’ preferences. With all the recent innovations in the additive manufacturing industries, now is the time to consider additive as a viable alternative to traditional manufacturing approaches and how to best take advantage of the design freedom it offers.

Additive Manufacturing: Two characteristics that facilitate this disruptive potential:

First, it enables the direct production of physical objects from digital design data, providing new opportunities for design freedom. Additionally, customized products can be manufactured without the high surpluses conventionally connected with one-of-a-kind manufacturing. Hence, current products or production processes can be substituted by additive manufacturing, which is making established companies anxious about new competitors.

Second, on the consumer side, additive manufacturing allows private and industrial users to design and produce their own goods (enhancing) the idea of the rise of the ‘prosumer”, which is further enhancing the competitive threat proposed by additive manufacturing to established firms.

Additive Manufacturing How is Different?

When you design products, you typically have to design around the manufacturing process, which results in additional costs, time, or even material. Imagine being able to fully combine what was previously a set of subassemblies into one manufacturable part. You have likely had to overdesign certain parts to withstand common manufacturing processes, which a dilemma that additive manufacturing can help you get around. When you design with AM in mind, you can forget about designing for anything other than functionality. Looking deeper into this, you can save time in the design process while also saving your client money in manufacturing costs relative to design complexity.

As engineers, we’re always thinking of new ways to improve components and designs. We have all had amazing ideas, only for them to crumble with the realization it would be nearly impossible to manufacture. With AM, you can enter the realm you previously thought impossible – releasing your full problem-solving potential. If you want to make internal voids or complex lattice structures, there’s a form of AM that can make it happen. The freedom and potential you can have in your future designs are immense if you cast off all design limitations. The path for pure unadulterated design can be paved with AM, although it can have some material and production limitations.

Traditional manufacturing techniques, such as CNC machining, place many restrictions on the geometry that can be created. Cutting tools have to get to the areas where you want to remove material. Often, that’s either not possible or requires multiple setups and complicated fixtures that significantly increase manufacturing costs.

But with Additive Manufacturing (AM) – commonly known as 3D printing – you can create more complex geometry and products with fewer components. For example, with AM, you could more easily design a model that needs fewer fasteners (studies show that fasteners may comprise only 5% of a bill of materials but account for 70% of the labor.

Additive Manufacturing Top Ten Advantages

1. The Cost of Entry Continues to Fall

You might worry that diving into any new manufacturing method demands a big upfront capital investment, but with additive manufacturing, that isn’t true. The cost of entry for AM is still falling. Industrial-quality printers are affordable, and so are the common materials. Of course, specialized methods and materials cost more, but for most needs, it’s easy to get into the game.

2. You’ll Save on Material Waste and Energy

The core definition of 3D printing is methodically adding material until a part is created. It starts with laying down a base layer of material, then adding subsequent layers until the part is complete. You may need to file off burrs or supports that hold up the part during printing, but the overall waste is minimal. Consolidating parts for manufacturing can also save energy and material costs.

3. Prototyping Costs Much Less

Rapid prototyping is now even easier on your time and monetary budgets, thanks to additives. The cost for a CNC milling setup is considerable, and its subtractive process piles up material costs. The expense of an AM prototype is comparatively cheaper.

The savings add up as you test iterate on using additive manufacturing. Make the necessary design adjustments print a new part, and you have near-instant proof (or not) that your updated design meets the requirements.

4. Small Production Runs Often Prove Faster and Less Expensive

If you need l0,000 0r more of a single, basic part, it might be worthwhile to set up a mold. However, if you require only a handful of the same part, it’s likely faster to print them. Gather design files, printers, and material, and you’re all set. For lower quantity product runs, almost nothing beats additive manufacturing for speed and economy.

5. You Don’t Need as Much On-Hand Inventory

Traditional manufacturing tends to stick you with a warehouse full of premade parts to draw from when you need replacements. And if you have a recall or eventually produce a better design, those old parts turn to scrap.

Additive manufacturing allows you to have a virtual inventory. You keep the part information in the cloud throughout the product lifecycle and then print on demand. That removes the need for warehouse space, personnel, and piles of obsolete parts. Your CFO will thank you.

6. It’s Easier to Recreate and Optimize Legacy Parts

Speaking of old warehouses…what if yours doesn’t have that legacy part you need? Worse, the machines that manufactured the part went out to pasture years ago. Loss of customer trust can impact repeat sales and loyalty.

AM to the rescue! As long as you have the specs or files (remember that cloud PLM?), you can almost certainly recreate it in a 3D printer: Moving toward a virtual part inventory lets you more quickly phase out the old physical inventory without having to make awkward apologies to upset end-users.

7. You Can Improve Part Reliability

As long as you’re recreating those old parts, now may be a good time to revisit your material options. New polymers, metals, and composites become available for AM every year. Now you can replace a regrettable part with something stronger Simply recreate a more reliable part as needed and save on future support calls and rework costs.

8. You Can Consolidate an Assembly into a Single Part

Traditional, complex parts require more manufacturing steps, along with more material and labor costs. The time to create and assemble them is longer, and it increases inventory. There’s a better way. With additive manufacturing, you can print the assembly as a single piece, saving money and time from start to finish.

9. It Uniquely Supports New Al-Driven Design Methods

Recently, design engineers have begun using artificial intelligence-driven generative design to create products. You simply set the constraints for a part, such as dimensions, materials, and manufacturing methods. The technology then suggests a number of designs that meet those requirements. As a result, designers spend less time iterating on the perfect design and more time engineering.

Because additive manufacturing can easily produce organic shapes, the generative design of the engine can make suggestions for designs few of us would have thought of on our own while still conforming to specs.

10. It Uniquely Supports Lattice Structures

Lattices like dragonfly wings are lightweight and strong, and difficult to create with traditional manufacturing methods. AM uniquely supports lattice structures that are intricate and tough, and useless material.

For single, solid pieces, injection molding does the trick. But it breaks down when lattices are introduced. Machining can work, but the cost is prohibitive when you need to remove material from multiple angles.

Additive wins the day, especially when used in concert with the Al-driven technologies we mentioned above. Paired together, they create reinforced parts and assemblies with minimal weight and material costs. That ultimately saves you money both in the creation and support down the road.

Credit source:https://www.ptc.com/en/blogs/cad/10-additive-manufacturing-advantages

Leave a Reply