Convergence Consulting believes that the process of Reverse Engineering is exceptionally beneficial because it accelerates the product development process and improves the quality of the products realized. So, first of all, we try to explain what is Reverse Engineering?

Every time we capture physical reality to use as part of our digital design process, we engage in reverse engineering. Whether we call it reverse engineering or something else, we are almost certainly measuring physical parts and using those dimensions to inform multiple aspects of our product designs.

#Summarizing What is reverse engineering?

Reverse engineering is the process of extracting the knowledge or design blueprints from anything already made. Reverse engineering is usually conducted to obtain missing knowledge, ideas, and design philosophy when such information is unavailable. In some cases, the data are owned by someone who isn’t willing to share it. In other cases, the information has been lost or destroyed. Traditionally, reverse engineering has been about taking shrink-wrapped products and physically dissecting them to uncover their design’s secrets. Such secrets were then typically used to make similar or better products. In many industries, the activity of reverse engineering involves examining the product under a microscope or taking it apart and figuring out what each piece does.

Reverse engineering is taking apart an object to see how it works to duplicate or enhance the object. The practice, taken from older industries, is now frequently used on computer hardware and software.

Hardware reverse engineering involves taking apart a device to see how it works. For example, if a processor manufacturer wants to know how a competitor’s processor works, they can purchase a competitor’s processor, disassemble it, and then make a similar processor. However, this process is illegal in many countries. In general, hardware reverse engineering requires a great deal of expertise and is quite expensive.

Every time you capture physical reality to use as part of your digital design process, you are engaging in reverse engineering. Whether you call it reverse engineering or something else, you are almost certainly measuring physical parts and using those dimensions to inform multiple aspects of your product designs. And you are probably doing this multiple times throughout each product lifecycle.

A modern approach to reverse engineering—backed by the latest measurement technology and software—can drive value throughout your business.

- Rebuild CAD data for legacy parts and tooling.

- Design new custom products that fit in, on, or around existing ones.

- Document changes made post-prototype or manufacture.

- Recreate non-existent or lost CAD data for parts and molds.

- Convert physical parts into CAD for new product designs.

As a practice, reverse engineering is as old as engineering itself. Thanks to continuing advances in hardware and software technology, the activity of reverse engineering is now so fast, accurate, and effective that it has become an integral part of modern product design.

Inspiring Great Design

Every great design is inspired by another.

Source:www.3dsystems.com

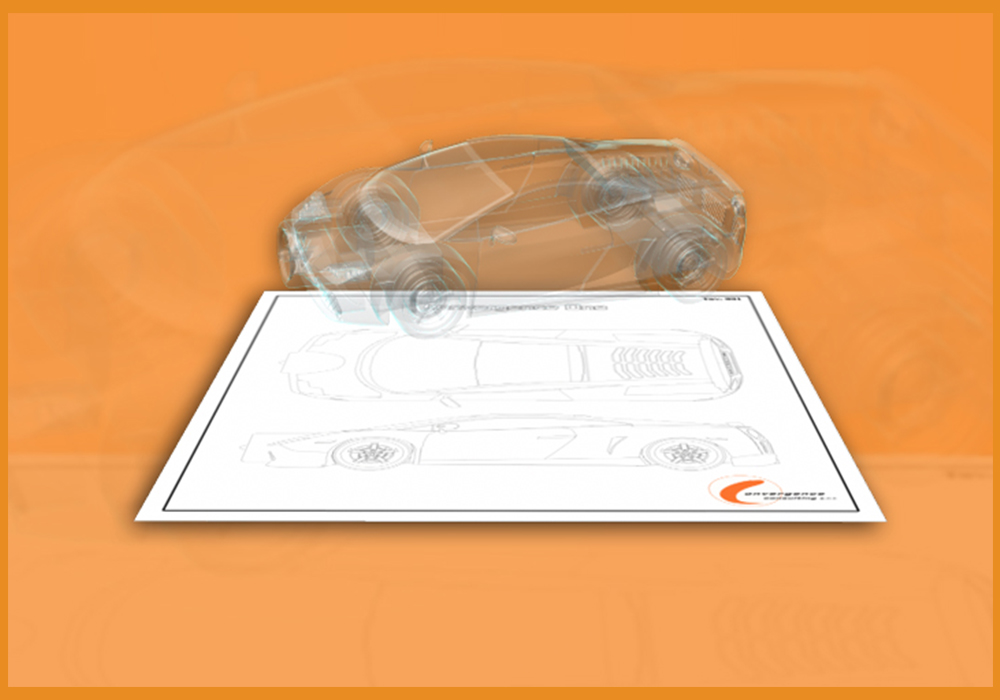

Convergence Consulting is deploying the best in class hardware and software of reverse engineering to drive business value throughout the design, manufacture, and maintenance of your products.

Some technology and concepts are synergic with the activity of Reverse Engineering Services.

- Additive Manufacturing Reapply design intent to generative mesh results from topologically-optimized parts and get feature-based results that you can edit and use within CAD.

- Product Design Significantly reduces time to market by using reverse engineering to combine off-the-shelf parts and assemblies with custom-designed parts.

- Redesign and Customization Start with an existing part—like a vehicle, vehicle component, or product that precisely fits the human body—and use it as a reference to create brand new or custom-fit parts.

- Prototyping Create manufacturable designs faster by digitizing hand-built prototypes and prototypes typically fabricated with foam, cardboard, or modeling clay.

#Top 5 Reverse-Engineering Implementation Checklist

Check out five key tips to adopt reverse engineering inside your organization successfully.

- Break down the barriers between measurement and design.

Directly involve designers in the scanning and scan-based CAD modeling process by having product development and engineering departments operate scanners directly or work closely within inspection/quality departments that operate scanners. - Identify multiple applications for 3D scanning and reverse engineering. Wherever possible, leverage reverse-engineering expertise and build stakeholder support across your organization to maximize your return on investment (ROI) and business impact.

- Select the right 3D scanner. Carefully select the 3D scanner that covers most, if not all, of your measurement needs and work with trusted outside service bureaus for the rest.

- Don’t use measurement software for design. Most bundled scanner software focuses on taking great scans—not applying design principles to extract the underlying functional intent of a part. Instead, use dedicated reverse-engineering software like Geomagic Design X for design.

- Avoid design software for measurement. Although it is tempting to use your existing CAD software to create CAD models from 3D scans, it is slow, cumbersome, and inefficient for regular use in reverse engineering. Specialized scan-to-CAD software like Geomagic Design X and inspection software like Geomagic Control X™ are must-haves for anyone serious about reverse engineering.

#Convergence Consulting would like to help you with the activity of Reverse Engineering Services :

- When missing CAD files

Many products do not have existing CAD files because developed with old CAD Systems or developed from suppliers that don’t exist or don’t work with you anymore. When CAD design files do exist, they may be 2D drawings or plans or out-of-date 3D files that do not reflect the as-manufactured product. Designers have to reinvent the wheel and spend significant time and effort recreating the designs from scratch. With the activity of reverse engineering Convergence Consulting enables you to recreate CAD files for existing products. - In Implementing a Modern Reverse Engineering

A modern reverse-engineering approach accurately captures the complete geometry of virtually anything that you can scan and yields editable, manufacturable 3D CAD models that meet specific engineering and manufacturability requirements. Besides, this process is faster, less expensive, and easier than ever before.

Some of the many benefits that Convergence Consulting offer with the activity of modern reverse engineering services include:

- Broadening your design capabilities

- Enhancing your CAD environment

- Accelerating time to market

- Leveraging existing assets

- Reducing costs

- Doing the impossible